【Ndustrial Design Product Development】 Cigarette Automation Equipment

Product Introduction

Folding leaf beater is a device to separate the leaves of tobacco leaves from the stems of tobacco, which can be divided into horizontal and vertical types. The blade beater is composed of two main parts: the blade beater and the air separator. The blade beater is a rotating roller, the cylinder surface is equipped with nails, and there are frame bars around the outside of the roller. The blade is torn from the tobacco stem by the relative action of nails and frame bars. The air separator divides the mixture after threshing into two parts, the leaf and the stem, by taking advantage of the different floating speeds of the leaf and the stem in the air. The tobacco stems with remaining leaves are sent to the next stage of threshing roll for treatment.

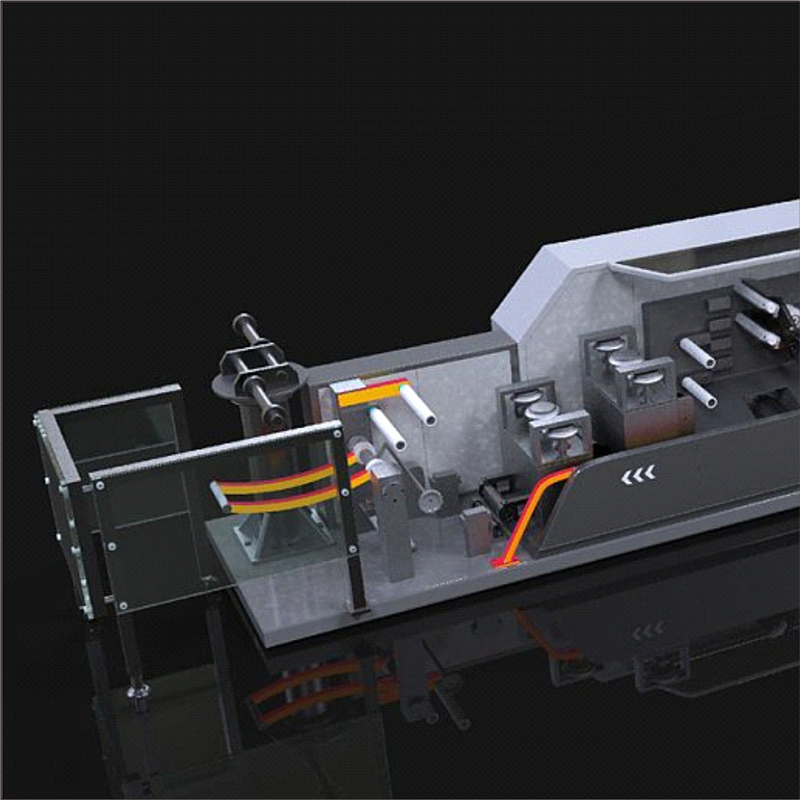

Product Display

Folding filter tip connector is a special machine for connecting filter tips to cigarette ends. The structure of the filter tip connector is based on the principle of parallel docking. It is first connected into a pair, and then cut into two filter tip cigarettes from the middle. The filter tip splicing machine mainly includes cigarette, filter tip, wrapping paper supply, splicing, butt cutting and detection. Most movements are accomplished by a series of rotating drums or sheaves. Grooves are uniformly distributed on the outer edge of the drum, filter rods and cigarette sticks are contained in the grooves, and holes are arranged at the bottom of the grooves, which are connected with the air pipeline through the distribution valve. Connect the negative pressure pipeline when the filter rod and cigarette need to be sucked, and connect the compressed air pipeline or atmosphere when the filter rod and cigarette need to be released.

Product Advantage

The folding filter rod forming machine is generally composed of pretreatment and rolling. ① The pretreatment part makes the filter material form a shape suitable for rolling, and its structure varies with the filter material. For acetate fiber materials, the operation of loosening the tow and applying plasticizer must be completed. Screw roll method and air nozzle method are the most commonly used methods for opening the tow. Most plasticizers are applied by centrifugal disc method or brush roller method. For paper materials, the paper core shall be folded in the pretreatment part. When the paper core is composed of multiple layers of paper, it also includes paper slitting. ② The coiling part is to wrap the initially formed filter material into strips and cut them into pieces. Its structure is basically the same as the coiling part of the cigarette machine, but the structure of the cigarette gun and the gluing part can be different. This is because the filter material has a relatively large rebound force during molding, which requires that the lap can be quickly bonded. High speed filter rod molding machines mostly use hot melt adhesive as the adhesive, and the lap can be accelerated by cooling after gluing.