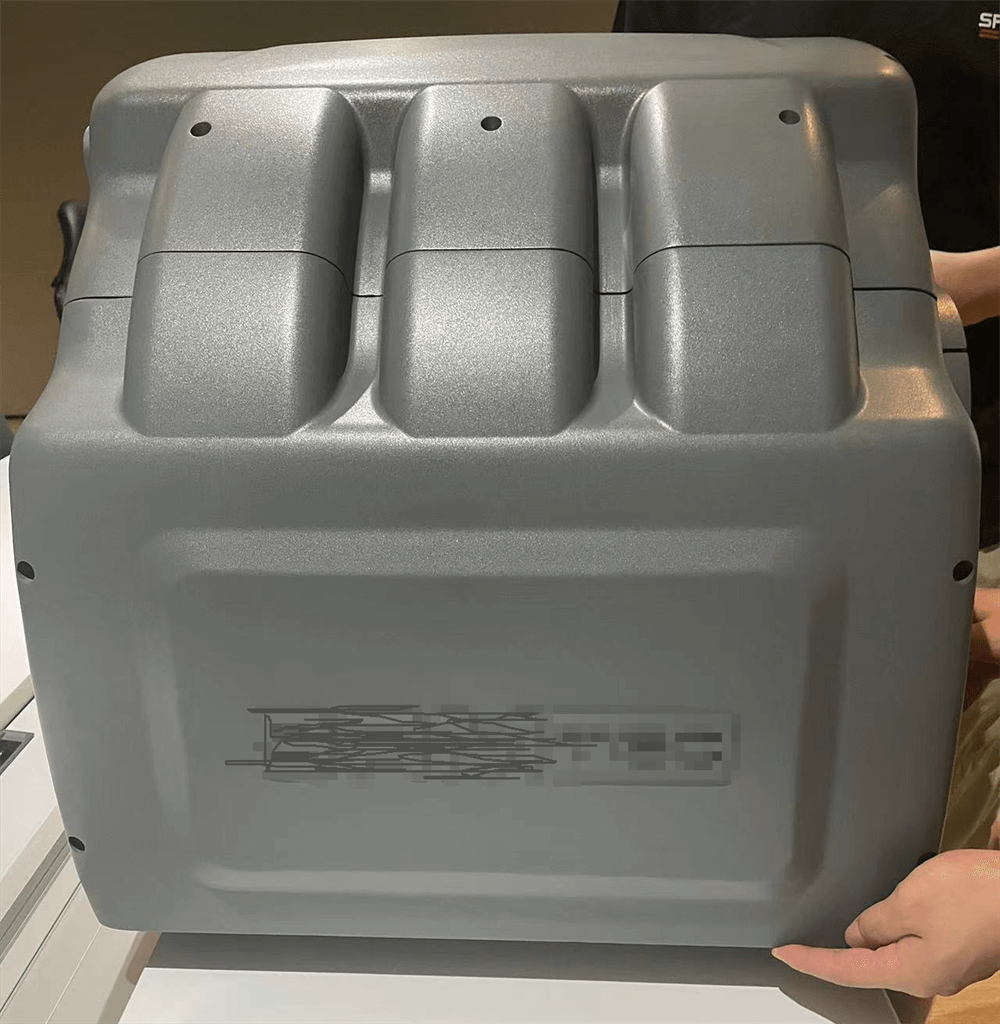

On November 14, the team of Blue Whale Industrial Design Company (lj product solutions co.,. limited) continued to manufacture the shell after receiving the project feedback from the company of Party A.

In the final phase of the centrifuge housing design, mass production, user research, internal assembly, economy, efficiency, hand testing and optimal functionality are key concerns. Here is a discussion of these keywords and the steps you need to take to achieve efficient and cost-effective mass production. Batch production: The success of batch production depends on a number of factors, such as material selection, production process design and production equipment preparation. Material selection and supply chain management: Determining suitable materials for mass production is critical. These materials need to meet quality standards and perform well in terms of supply chain reliability. In addition, it is crucial to establish stable supply chain relationships to ensure that materials are available. Production process design: Production process design must take into account production efficiency and cost. It is important to ensure that the design of the enclosure can be produced in an efficient manner and reduce costs while maintaining quality. Preparation of production equipment: select the production equipment suitable for mass production, and ensure the stability of the equipment, as well as relevant staff training. User Research: The importance of user research cannot be overlooked. It is the key to understanding user needs and developing improvement measures. User needs research: Through in-depth understanding of the needs of potential users, we can better meet their expectations. This includes expectations for the shell design and feedback during use. User experience design: In the design process, emphasize the importance of user experience. Only in this way, the shell design can really meet the needs of users, thereby increasing the competitiveness of the product. Feedback loop: It makes sense to have a user feedback loop. Continuously use user feedback to improve the housing design and respond to changes in market demand. Internal assembly: The housing design must take into account the layout and installation of internal components to facilitate internal assembly work. Internal component design: The shell design should take into account the layout and installation of internal components to reduce assembly complexity and cost. Assembly process flow: Design a reasonable assembly process flow to ensure that the assembly process is efficient, stable, easy to operate, and does not affect the overall performance. Economy: Cost control is crucial in the design process. Cost analysis: Cost analysis of all aspects of the entire production process to find out the potential for cost reduction. Design optimization: Through reasonable design optimization, reduce production costs and improve production efficiency. Manufacturing efficiency improvement: Improve manufacturing efficiency and reduce production costs through lean production and other methods. Efficient: The ultimate goal is to achieve efficient product production. Production process optimization: Optimize the production process to improve production efficiency and product quality. Quality management: Establish a sound quality control system to ensure production efficiency without affecting product quality. Manual testing: Performing manual testing is part of ensuring that the shell design meets optimal functionality. Prototyping: Design and manufacture handboard prototypes in order to test the performance of the housing design in actual use. Test feedback: According to the results of the hand-board test, necessary corrections and improvements are made to the shell design to achieve the optimal function. Optimal functionality: Optimize the shell design for optimal functionality. To sum up, the centrifuge housing design is coming to an end, and it needs to focus on mass production, user research, internal assembly, economy, efficiency, hand testing and optimal function. Only when these key elements are fully considered can efficient and economical mass production be achieved.

Post time: Dec-15-2023